MTA Queensland Launches ADAS Training Courses

The automotive industry is, as we all know, facing a level of disruption and technological advancement that is as great as it has ever known in its history.

From the electrification of vehicles through battery, hybrid and fuel-cell technology, to the incredible advances in safety standards through new and ever-improving driver assistance systems, vehicles are evolving quickly and the industry with it.

Safety has always been a priority, of course, and researchers, tech companies and automotive manufacturers have been making great strides in this area, developing sophisticated software and hardware that deliver incredible features – such as adaptive cruise control, lane keep assist, blind-spot monitoring, and autonomous emergency braking – that are designed to make driving safer and easier, mitigating the chance and severity of accidents.

Collectively, the sensors, software and computers that make these safety features possible is called ADAS (Advanced Driver Assistance System) and, in just the past few years, it has become common technology with almost no new model of car being launched without at least a handful of these safety features.

Take, for example, the venerable Toyota Camry. Today, according to the company’s Australian website, you can get an Ascent model with Toyota Safety Sense – a system that offers, amongst other features, Lane Departure Alert, Pre-Collision Safety System with pedestrian detection, Automatic High Beam and All-Speed Active Cruise Control – as well as Anti-lock Braking with Electronic Brake-force Distribution and Brake Assist, Vehicle Stability Control and Traction Control, Hill-start Assist Control and Brake Hold, plus a Reversing camera with moving guidelines. Move up the model range and you can add Blind Spot Monitor with Rear Cross Traffic Alert, front and rear clearance sensors and more.

You get the point. 15 years ago, barely any of these features existed, but safety technology has evolved to the point that an entry-level new car comes stuffed to the grilles with powerful, ADAS functionality.

Crucial to all those features working effectively are the sensors – the gadgetry located strategically on the vehicle that scans the area around it and feeds massive quantities of data to the ECU computers to be processed.

While different manufacturers may use different sensors in different configurations, these sensors will likely include LiDAR (Light Detection and Ranging), which emits a pulsed laser to measure the range to other objects; Radar (Radio Detecting and Ranging), which uses radio waves to determine the range and speed of objects nearby; Ultrasonic sensors (that send out sound waves to determine the distance to objects); and, of course, cameras, that rely on ‘seeing’ the space around them.

Keeping these sensors maintained and set to manufacturers settings is vital – when they are not working as intended, safety is compromised – and every sector of the automotive industry must take them into consideration when doing their work. If a job requires the removal or repair of just about any element of a car – from a windscreen or a bumper, from a grille to a body panel – then it’s very likely, especially on the newest car models, that an ADAS sensor will need to be recalibrated.

While ADAS systems are common, they are complex and, relatively speaking, a new technology. Getting to grips with what it does, how it works, and the requirements of working with it and its calibration, demands training, and that is where MTA Queensland steps in.

MTA Queensland ADAS Courses

As the peak body representing the interests of Queensland automotive businesses, part of MTA Queensland’s mission is to offer members opportunities to upskill and train in a number of areas. In March, the Association expanded its training offerings by launching ADAS-specific courses in partnership with ADAS Solutions Australia – a Brisbane-based company that specialises in ADAS equipment sales and support, calibration services, and training.

Three ADAS courses are being offered – ADAS Awareness, ADAS Technician, and ADAS Vehicle Glass – and the decision to launch the courses is a reflection of how important and ubiquitous ADAS systems have now become and how they will affect every sector of the automotive industry.

“Most, if not all, businesses will need to have at least some understanding of this technology,” said Anthony Bonaccorso, MTA Queensland Senior Business Development Manager. “However, for some, such as those involved in auto glass and collision repair, it is something they simply must know.

“Where possible, MTA Queensland offers the industry new technology training as it comes to fruition. Whether it’s PDR, HEV/EV, Diesel Particulate Filter technology, or ADAS, it all plays a vital part in today’s vehicle maintenance and care and, at MTA Queensland, we have a responsibility to engage with and help industry as these technologies take hold. These ADAS courses are the latest additions to our training opportunities and will be invaluable to anyone in the industry who takes the arrival of these very complex systems seriously and wants to understand fully how they work and what they mean for their business.”

The challenge for the auto industry to understand and work effectively with ADAS systems is a point reinforced by Adrian Parkes, founder of ADAS Solutions Australia.

“We are on the cusp of radical change and there is a real awareness gap,” said Adrian.

“The industry must grasp the importance of the need to understand ADAS and what the implications are of repairing these vehicles. At all levels of the industry, we need to understand what we are doing, what we are removing, what we are refitting, and what the implications are when we do that.”

The three ADAS courses on offer deliver a pretty complete look at the technology.

The ADAS Awareness course is aimed at business owners, estimators, assessors and people who need to understand what ADAS is, need to know the fundamentals, and may have a workplace requirement to identify ADAS components. It is a comprehensive introduction to the technology.

The ADAS Vehicle Glass course focuses on windscreen-mounted cameras – perhaps the most common ADAS-related component today, and one of the earliest pieces of ADAS technology to appear on cars.

“Our autoglass course offers an overview of fundamentals and diagnosis but is also hands-on on how to calibrate and set up the camera,” said Adrian. “We show how that is done, and done properly, to get a successful outcome.”

The two-day ADAS Technician course is aimed at those with prior ADAS diagnostic experience and offers a deep dive into the technology.

“This is an all-encompassing course,” said Adrian. “It covers all the fundamentals – the technical information; all facets of radar, lidar, and 360-degree view systems; as well as diagnosis and fault-finding techniques; the risks associated with incorrect repair method and much more. That course will see us in the workshop, working on a car’s systems, looking at data, calibration methods and actually preforming calibrations.

“In the absence of a qualification in the Australian system – and we may be still some way from having anything within the AUR system – these courses represent the best introduction and training in ADAS.”

In March, MTA Queensland and ADAS Solutions delivered the first of the courses on ADAS Awareness.

Amongst the participants was Mick Hamilton, Hail Repair Commercial Manager for the Action Smart Group – a market leading hail repair specialist.

While Action Smart Group does offer ADAS calibration as part of its repair services, Mick said it was always useful to gain more insight and information, and that being across new technology is a priority.

“Adrian was very informative and has a great deal of knowledge about ADAS, so it was a very good day,” he said. “Manufacturers are looking for repairers that are fully aware of the features on their vehicles so they can be repaired correctly and properly, so you have to stay up to date or you fall by the wayside.

“Information is king. The more you understand about a motor vehicle – about how it is put together and about its features – will only assist everybody in the long run.”

Also in attendance was Scott Wiseman, National Key Accounts & OEM Manager – Refinish for Axalta Coating Systems.

“Attending the ADAS Awareness course was a real eye-opener in terms of not just what is in the marketplace now, but continuing technological advances from the OEMs coming down the pipeline,” said Scott.

“Axalta, as a key industry participant, is very focused on the broader collision industry, both here and globally, and understanding what the challenges and impacts are for repair facilities. One of the ways we support the industry is by rolling our sleeves up and getting into the detail of the coal-face issues, and ADAS is a key issue challenging all segments of the industry, both now and into the near future.

“It is important for Axalta’s teams of Technical and Business Services consultants to be abreast of this, so we can help develop solutions for both our customers and the industry more broadly, and we would encourage industry participants looking to further their knowledge to consider this or other similar education courses to remain at the forefront of the advances in vehicle technology.”

What is ADAS Calibration?

ADAS calibration essentially boils down to using targets and reflectors to realign the various sensors back to OEM requirements. That sounds simple enough, but the technology – as it is used in cars – is relatively new, and there are plenty of considerations to be taken into account.

There are several manufacturers of calibration equipment – Autel, Hella, Bosch, and Texa are, perhaps, the best known – and several different pieces of equipment may be required for the calibration of different types of sensors: Lidar requires one type of instrument, radar and cameras another, night-vision (infrared) another, and so on. Even headlights, which can be very sophisticated, may require their own calibration equipment.

Beyond that, there are two different types of calibration processes – dynamic and static.

“Dynamic means the calibration is done on the road and, in that case, we use diagnostic software to instigate calibration and then drive to meet the requirements of that calibration,” explained Adrian. “Some manufacturers – including Ford, Holden, Jeep, Chrysler, and BMW – do favour this type of method.”

Taken into consideration during a dynamic calibration, and depending on the requirements of the vehicle manufacturer, are things such as speed, whether a road is straight or curved, looking at road signs, looking at white lines, looking at barriers, and maintaining a set distance from a moving vehicle ahead.

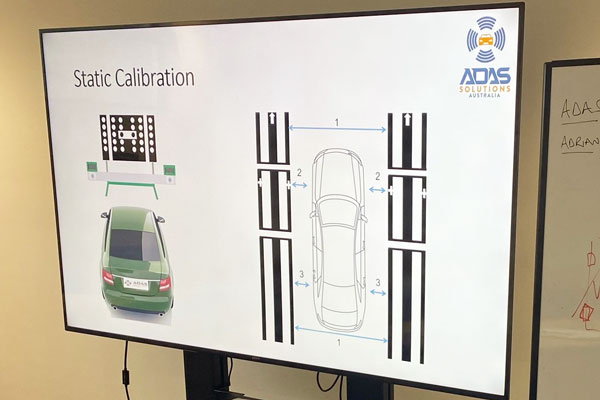

“A static calibration takes place in a workshop and strategically placed hardware – such as a target, a reflector, a doppler or night-vision calibrator – is used to perform that job,” said Adrian. “Some manufacturers, including Subaru and Toyota, favour static calibration for their models.”

It is, in fact, the requirements of the calibration process that makes ADAS something of a dilemma for the automotive industry.

The complexity of the technology, the different makes of ADAS components, the number of calibration instruments that may be required to service all those components, and the different requirements of vehicle manufacturers, can make the investment in offering a full calibration service a heavy burden for any business. On top of that is the environmental requirements for each type of calibration process.

For the dynamic calibration, a vehicle must be taken out on the road and run through a variety of measurement and alignment processes. Some of these require that a vehicle be run at a certain speed for a certain length of time – an option not always available for businesses in a city or town where traffic is heavy.

“If we take the dynamic calibration for a Ford Ranger, for example – amongst other things, the calibration requires that it be able to lock onto another vehicle in front of it that is travelling over 55km/h, and do so for about 15 minutes,” said Adrian. “Put yourself in a major city such as Melbourne on a Friday afternoon and its unlikely you’ll be able to do that, and you might even have to head out of town. That is time-consuming.

“You are also somewhat at the mercy of the weather. A dynamic calibration requires the sensors to see traffic signs, white lines on the road, barriers and so on – and in particularly poor weather that may be a problem.”

While a static calibration means the environment can be controlled, the dilemma here is also one of location.

“A static calibration requires space, and that is something that workshops, even dealerships, may not have,” said Adrian. “For example, for a calibration on the front radar of a Maxda CX-9, the OEM requirement is that the equipment be set up five metres in front of the vehicle and that there be another five metres of space beyond that. The vehicle itself is five metres long, so that all adds up to 15 metres of space being needed for just that job. That is a lot of space to find in any workshop.”

All this is relatively new to the industry and, as with other technological developments in automotive, the evolution and uptake of ADAS systems moves fast.

“In the last 12 to 18 months, it has developed very rapidly, is being adopted by everyone, and is in just about everything on the road. And the automotive industry has to come to terms with that,” said Adrian.

“I’ve been in the industry basically all my life and while I’ve seen changes in the industry, they have been relatively subtle. ADAS is the first thing that has come along that is totally outside of the industry norm and concerns components – such as radar and lidar – that are not typically automotive.

“Not surprisingly, there is an awareness gap within industry, and I hope that we can, through courses such as the ones we are delivering with MTA Queensland, raise that awareness. If you are in the industry, you need to know. You have to know.”

Source: Motor Trader e-Magazine (April 2021)

12 April 2021